Safety, Quality and Reliability.

NectarTek is an ISO-certified high-volume extractor of hemp. We produce CBD isolate and distillate. Headquartered in Pahrump, Nevada, with facilities in excess of 35,000 square feet, our experience and team enable us to consistently deliver on our promise of rapid, on-time processing of hemp and production of the highest quality CBD isolate and distillate.

NectarTek’s business model is built on a foundation of tested, safe processes, transparency, rapid inventory turns and reliability. We seek to do business with farmers that supply and markets that seek product of the highest quality and consistency.

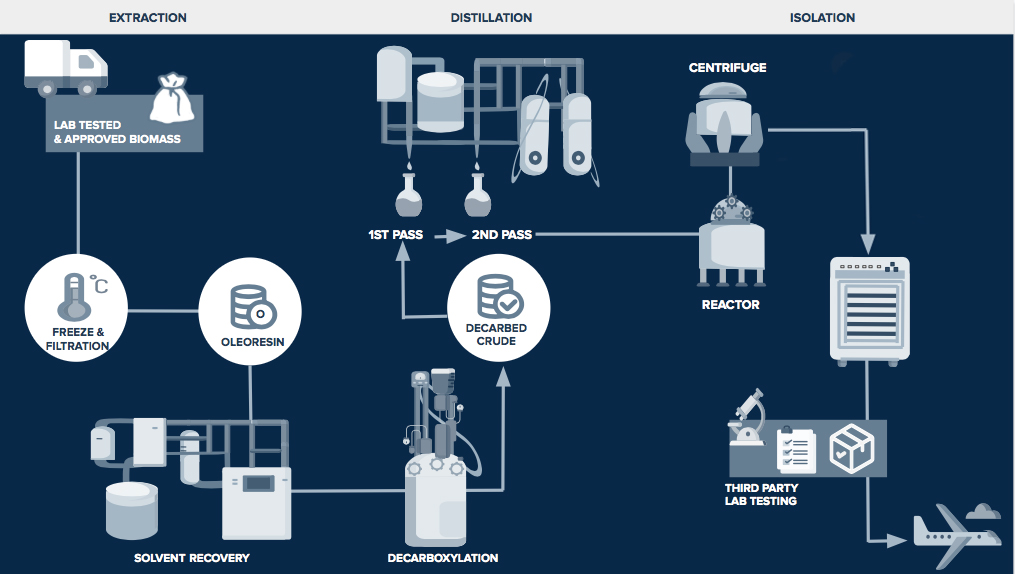

Our Process

1

Receive and Quarantine Biomass for Lab Testing Accept or Reject Biomass Prep & Wash Biomass with Cold Ethanol

Centrifuge Comes out at 90% Ethanol, 10% Plant Oils

Centrifuge Comes out at 90% Ethanol, 10% Plant Oils

2

Freeze Oleoresin

Filtrate Oleoresin overnight

Filtration system: 1 Micron System, Charcoal System, 1 Micron System to remove Charcoal

Removing fats, lipids & chlorophyll

Filtrate Oleoresin overnight

Filtration system: 1 Micron System, Charcoal System, 1 Micron System to remove Charcoal

Removing fats, lipids & chlorophyll

3

Receive Oleoresin Still at 90% Ethanol

4

Solvent Recovery Kits Oleoresin gets Pumped into the Steam Tunnel

Raw Crude Separated Ethanol More than 80% Ethanol Reclaimed

Raw Crude Separated Ethanol More than 80% Ethanol Reclaimed

5

Raw Crude goes under Decarboxylation Process to Obtain Decarbed Crude

6

Full Spectrum Decarbed Crude

7

Distillation Systems

Oil Refining First Pass

Oil Purification Second Pass

Oil Refining First Pass

Oil Purification Second Pass

8

Second Pass Distillate goes into 150 Lt Reactor to homogenize

Gets moved to a 50 Lt Chilling and Mixing System Reactor to mix with Solvent

Comes out as Slurry

Gets moved to a 50 Lt Chilling and Mixing System Reactor to mix with Solvent

Comes out as Slurry

9

Wash Slurry in Centrifuge Mixed with othe Chemicals

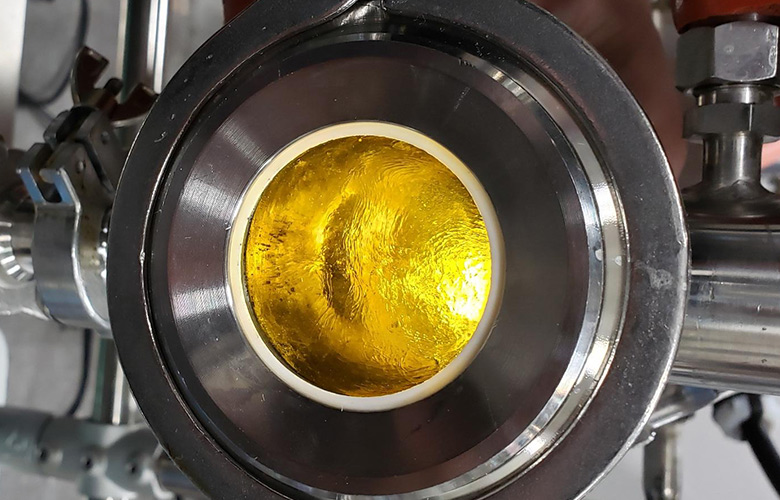

Comes out as a Pure White Isolate

Comes out as a Pure White Isolate

10

Stored in Vacuum Ovens for 12-24 hours

11

Accredited third-party lab validation Packaged according to cGMP clean rooms.

12

Shipped around the world.

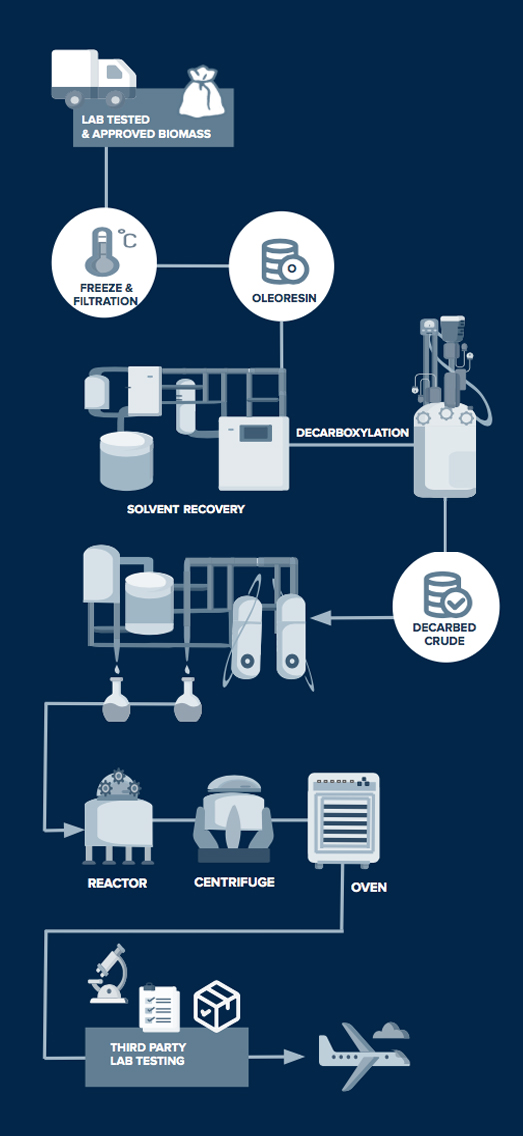

1

Accept or Reject Biomass

Prep & Wash Biomass with Cold Ethanol

Centrifuge Comes out at 90% Ethanol, 10% Plant Oils

Removing fats, lipids & chlorophyll

Prep & Wash Biomass with Cold Ethanol

Centrifuge Comes out at 90% Ethanol, 10% Plant Oils

Removing fats, lipids & chlorophyll

2

Freeze Oleoresin

Filtrate Oleoresin

Filtrate Oleoresin

3

Receive Oleoresin Still at 90% Ethanol

4

Raw Crude goes under Decarboxylation Process to Obtain Decarbed Crude

5

Decarboxylation Process to Obtain Decarbed Crude

6

Full Spectrum Decarbed Crude

7

Distillation Systems, Oil Refining First Pass Oil Purification Second Pass

8

Second Pass Distillate goes into 150 Lt Reactor Then moved to a 50 Lt Reactor to mix with Solvent Slurry

9

Wash Slurry in Centrifuge Isolate Comes Out as a Pure White Isolate

10

Stored in Vacuum Ovens for 12-24 hours

11

Accredited third-party lab validation Packaged according to cGMP clean rooms.

12

Shipped around the world.